What To Consider In Selecting Order Fulfillment Services

While society fulfillment is, by definition, the method by which a company processes a sales club to the customer'due south specifications, that understates its importance. Customers concord more than ability than always, are more informed and take higher expectations. Efficient club fulfillment is key to your brand's reputation, your company's profits and your ability to retain clients.

Without sales there is no business. Without order fulfillment, there are no sales.

Video: What Is Order Fulfillment?

Key Takeaways

- Order fulfillment is a critical business job for many product-based businesses.

- An efficient guild fulfillment functioning requires coordinating with multiple departments and outside partners.

- An ERP oftentimes plays an essential office in managing the club fulfillment process.

Order Fulfillment Explained

A new sale is near ever something worth celebrating, but the work isn't done until the order is fulfilled, and the customer has the order in paw. Order fulfillment is the critical task of assembling the social club and shipping it off to the client, plus the supporting processes that support those tasks.

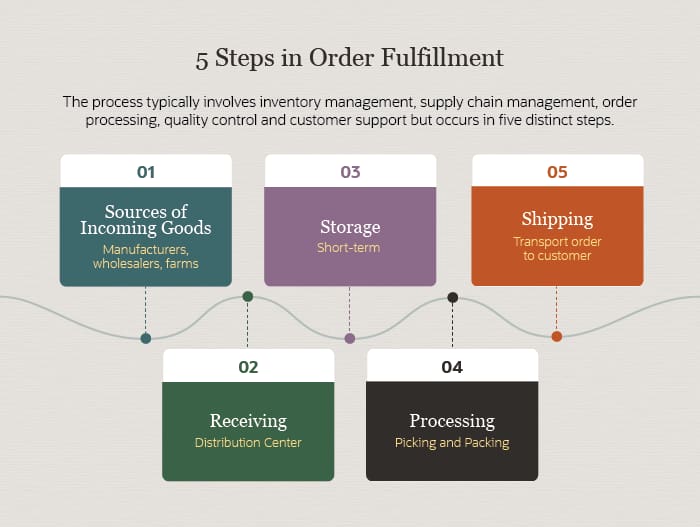

The complete guild fulfillment lifecycle is made upwardly of five chief steps starting with strategic sourcing and ending with aircraft. Many businesses include inventory management, supply chain management, order processing, quality control, and client support in the umbrella of order fulfillment.

Much of the order fulfillment process can have place under one roof in a well-organized warehouse, depending on the size of your business. Many small-scale businesses handle order fulfillment themselves in-house through a simple process. Large enterprises require a more complex, multi-layer distribution heart strategy. Merely in either case, the master goal is efficiently getting the client what they ordered equally quickly, reliably, and inexpensively as possible.

Order Fulfillment Process: How Does It Work

The order fulfillment procedure takes place in i or more than distribution centers and typically involves inventory management, supply chain direction, order processing, quality control and support for customers that need to report problems or brand production exchanges or returns.

-

Receiving Inventory

Goods may come from a tertiary party, another company department or a company warehouse; a pipeline (as with oil, fuel, water or some other fluid product); as digital data from a database; or in a variety of forms from other external or internal sources.

In any example, the incoming inventory must be counted, inspected and inventoried to ensure the proper amount was received and the quality is acceptable. SKUs or bar codes on the arriving products are used in the receiving and storage processes, and to call up appurtenances from internal storage later.

-

Inventory Storage

Once goods are received in the fulfillment center, they are inventoried and either immediately disbursed or sent to short- or longer-term storage. Items are ideally stored just long plenty to help organize the orderly distribution of goods for existing sales, rather than to concord product for future sales.

-

Order Processing

An society processing management system dictates the production picking and packing activities per each newly received customer order. In the online market place, order direction software can be integrated with the shopping cart on an ecommerce website to automatically initiate lodge processing.

-

Picking

A picking team or automatic warehouse robots select items from the warehouse according to a packing slip's instructions. The packing slip contains specific information, such every bit a list of item SKUs, product colors, sizes, number of units and location in the distribution middle's warehouse.

-

Packing

Packing materials are selected by a packing team or automated fulfillment robots to reach the lowest practical dimensional weight, which is calculated by multiplying parcel length times width times height. Since infinite on delivery trucks is at a premium, optimizing dimensional weight (or DIM weight) is of import to speed send while also potentially lowering shipment costs.

Further, packing teams frequently include return aircraft materials and labels in example the client wishes to exchange or return the particular for a refund later.

-

Shipping

The order is sent to a transportation aqueduct or aircraft node to exist shipped to the customer. Shippers and carriers—be they freight lines or airlines, FedEx, UPS, the U.South. Postal Service (USPS) or other carriers—determine freight billable costs by whichever is greater: actual bundle weight or its dimensional weight.

Even if the bodily weight is low, such as with a t-shirt, packing it in the lowest DIM is oft worth it to keep the packaging from adding significantly to the overall parcel weight. Also, most carriers take packaging rules to optimize their ain profits from the shipping space they have available. Failing to meet those requirements can delay shipments if carriers refuse to take the order.

-

Commitment

Information technology is common for shipping routes to include more than one carrier. For case, FedEx may selection up a package at the fulfillment center that will later on exist delivered past the USPS to the customer's dwelling. There are many reasons for these hybrid aircraft methods. One mutual case is that the USPS delivers even to remote areas where near other commercial carriers do not. It'southward simply more practical to utilize the USPS for the last mile of delivery in those cases.

-

Returns Processing

Returns processing begins with including shipping materials and a render label with the original customer's order. When a client does return a product for exchange or a refund, the process must be executed carefully to ensure it's appropriate to restock it. Obviously if the product malfunctions, it can't be restocked. Nor can a soiled item. Returns processing involves quality control checks and sorting returned products accordingly. Return products are then restocked, returned to a vendor or manufacturer for a distributor refund or credit, or sent to a recycling centre.

Why Is Order Fulfillment Important?

Companies make money by selling goods, products and services to businesses or directly to consumers. No matter whether you're B2B or D2C, the auction is not complete until the sold items are received past that customer. Social club fulfillment is how companies consummate the auction and information technology'due south at the eye of every business concern.

Order Fulfillment Challenges

Order fulfillment challenges run the gamut from supply shortages and inventory management issues to failures in need and logistics planning to kinks in the supply chain.

Inventory Management

Running out of stock leads to customer dissatisfaction, failures in the overall client feel and harm to brand reputation. It is difficult for companies to repair the damage once it's done. Simply there are exceptions: Customers tend to be more forgiving if shortages and delays are caused by a widespread weather effect, a natural disaster or a Black Swan event.

Need Planning

On the other manus, keeping also much stock on hand drives up storage and carrying costs. It as well increases your take a chance since demand for those items may driblet before y'all get them sold. It's important to carefully predict and plan for demand levels in order to keep adequate supplies in stock without ever dipping too low or stocking too much of whatever given item.

Logistics Planning

Slow or missing deliveries, cleaved items and dilapidated or wet packaging are all factors that tin can harm a company's reputation and time to come sales, and in plow its profitability. It is essential and then to advisedly manage logistics then shipping doesn't go awry and items aren't damaged. Simply put, customer satisfaction is greatly affected past logistics, and then continue a close eye on terminate-to-end—or warehouse to mailbox—performance.

Supply Chain Execution

Having a supply chain strategy entails evaluating cost versus benefit tradeoffs in terms of operational choices. For instance, a company may choose a sole supplier for a given production to gain price breaks for the higher purchase volume. That'due south also a expert strategy to gain priority status with the vendor, which can make a difference in getting goods on time during periods of loftier demand. All the same, using a sole supplier model tin can backfire if anything goes incorrect for that vendor—from employee strikes to natural disasters to their own supply shortages.

Supply concatenation execution (SCE) is the flow of tasks in the supply concatenation. Software applications are used to manage every activity within that concatenation. Specifically, cloth management, tracking the physical status and movement of the production, tracking data shares and data feeds, and managing financial information—specially transactions amidst all parties.

SCE typically involves the use of multiple applications, such equally order management, inventory direction, warehouse management, transport management and logistics software.

Club Fulfillment All-time Practices

Recall that the efficiencies to be gained in order fulfillment depend on nifty organisation. Best practices eddy down to organize, organize, organize.

Start with the basics. Streamline your receiving processes so incoming shipments are candy chop-chop and damaged goods returned swiftly to the manufacturer for replacement. This volition go a long way in preventing back-orders or long wait times for your customers.

Organize your warehouse for more efficient picking times. Place hot-ticket items upfront and shut to man or robot pickers and packers. Identify other items in your warehouse according to demand, with items least in demand being at the very dorsum.

Organize shipping and logistics and then y'all get the fastest possible commitment times to customers at the least price. But likewise plan a shipping backup strategy in case something goes wrong, or carriers unexpectedly raise rates too high for your margins.

Automate as much equally you can to salve labor costs, ameliorate working conditions, and make operations safer.

How Practise You Cull an Order Fulfillment Strategy?

Businesses have several choices when deciding on an lodge fulfillment strategy. Depending on the skills and resources bachelor in your visitor, y'all may adopt either internal fulfillment or outsourced fulfillment.

If you take the means in-business firm, you gain more than command over operations and costs by handling fulfillment internally. If your visitor'south in-house talent and resource are somewhere in the middle, you may want to opt for a hybrid model to requite you some of the benefits of both worlds.

If fulfillment and logistic skills and resources are scarce, you may be better off outsourcing order fulfillment completely. This allows your team to focus its efforts on producing and selling the product, and it oft leads to more predictability. With internal fulfillment, you use the staff, own the warehouse, and have to make certain every order goes out perfectly. When y'all outsource social club fulfillment, many of those challenges are no longer your problem.

To make the correct decision for your business, expect at the product, potential fulfillment options, and fulfillment costs. A detailed fiscal analysis should guide you to the best solution.

Order Fulfillment Models

Order fulfillment models take been refined over many decades, but the nuts hold true, and that is for very sound business reasons.

What are the types of order fulfillment?

There are iv order fulfillment models to choose from: in-business firm, outsourcing, drop shipping and hybrid. Each model fills specific concern needs.

- In-house: The in-business firm model simply means that all steps in lodge fulfillment are performed internally.

- 3rd-party: This model entails outsourcing all order fulfillment activities to an lodge fulfillment vendor or other 3rd-party.

- Drib aircraft: The order is produced and shipped by the manufacturer. On the pro side, this lowers the barrier to entry and minimizes overhead costs, key for startups and ecommerce companies. Information technology as well eliminates the middleman, which tin potentially salvage the buyer money. On the cons side, it can as well strip control from merchants, specially in terms of inventory management and order fulfillment. It tin can also profoundly delay shipments to customers, since many manufactures are in other countries, far from the merchant's customer base. In that case, shipping may accept more time and toll more or a distribution center is fix upward and items ship from there.

- Hybrid: A hybrid model simply means a combination of two or more than of the three models to a higher place. For example, a company may choose to handle order fulfillment of all or just popular products internally, only too choose to outsource fulfillment during peak periods, such as the holidays, and drop transport big and bulky items directly from the manufacturer.

7 Tips to Improve Order Fulfillment

Companies managing their own order fulfillment process should plan ahead for a smooth order process that's automatic where possible. Using a fully-featured ERP helps you track orders, inventory, and shipments from end-to-end for enhanced visibility, the all-time client and employee experience, and ideally maximized profits.

- Choose the best order fulfillment ERP system: Commencement by choosing a system that offers finish-to-end tracking for orders, inventory, and all other aspects of your business. An ERP like Oracle NetSuite features helpful modules to assist you and your team track the unabridged business organization, including order fulfillment, finances, and homo resources, through ane secure, cloud-based organisation that's always accessible.

- Integrate with suppliers and vendors: Modernistic ERP systems enable you to integrate directly with suppliers and vendors. For case, your entire restocking and accounts payable procedure can tie together and run without extensive human intervention. Set up your rules, connect with your vendors and suppliers, and your systems can handle things from in that location.

- Fix clear customer expectations: Most businesses are wise to heed the business adage to "under hope and over deliver." Customers are likely willing to work with you and your expected timeline, particularly in the post-COVID era where delays are commonplace. Set articulate expectations when y'all receive an order, then work hard to meet those expectations. If anything looks to exist delayed, communicate the issue every bit soon every bit possible so your customer knows what to look and isn't disappointed.

- Optimize inventory direction: If you hold as well little inventory, you risk running out of stock and coming upward curt for a client order. When yous concur likewise much inventory, working capital and storage costs may spiral out of control. A quality inventory management module in your ERP is tremendously helpful for this chore.

- Select the right society picking strategy: When an order comes in, chances are yous don't have a fleet of automated warehouse robots to pick and package orders. Using your human capital effectively is vital to keeping costs down and efficiency upwardly in your lodge fulfillment operation. Common order picking strategies include discrete order picking, where orders are picked 1 at a time, zone and batch order picking, where multiple orders are picked at once, and other strategies intended to limit travel time and increase picking speed.

- Care for your shipper as an essential partner: Organizations like the United States Mail, UPS, FedEx and DHL play a key function in your fulfillment process. Don't treat your shipper like any other vendor. Spend the time and effort negotiating the best deal and delivery schedule for your fulfillment needs, and piece of work proactively with your shipper to avoid delays.

- Prepare for client service and returns: As much as you try to leave every customer with a perfect experience, mistakes, defects, and delays happen from time to time. Whether the effect was your mistake, your customer'southward, or a vendor'southward, it's best to exist prepared to make information technology right.

Improve Order Fulfillment with Order Management Software

When edifice your order fulfillment process, don't discount the value of high-quality order management and fulfillment software. When you utilize the right ERP, these systems seamlessly work together, enabling the nearly efficient and enjoyable sales process possible.

When you shop online, you may not realize that yous're interacting with a series of interconnected systems to handle ordering, shipping estimates, payments, warehouse fulfillment, and delivery. Some companies cull a hodgepodge approach where they use different tools for each other these functions while others choose an guild management software that fits into a larger ERP strategy.

NetSuite Guild Management is a office of the NetSuite ERP that brings owners, managers, and fulfillment teams quick access to essential data as the organisation tracks every order through your sales and fulfillment process. Users tin can securely view and whatever order, and the arrangement handles complex gild needs such as split up orders and outsourced driblet shipping.

The Order Direction module enables ordering, fulfillment, and returns from anywhere in the world with a single information ready and automatic order management process. That's a large help for whatsoever business involved with order fulfillment.

Whether you lot're are the heady beginning stages of a startup or have decades of gild fulfillment experience, it's never too late to look at your guild fulfillment and management systems with fresh eyes. You could find opportunities to cutting costs while offering an improved customer experience. That's a win-win for any concern, and its valued customers.

Club Fulfillment FAQs

What does it mean when an social club is in fulfillment?

This generally means that the order is somewhere in the fulfillment process just not even so shipped.

What is guild fulfillment rate?

The order fulfillment rate is an efficiency measurement calculated by dividing the number of orders already processed by the total number of orders. It is also called the social club fill rate.

Order Fulfillment Charge per unit = Full number of orders procedure / Total number of orders

What is the social club fulfillment process?

The gild fulfillment process typically involves receiving goods, curt-term storage in a warehouse in the distribution center, customer order processing (picking and packaging) and shipping and logistics.

What are the seven steps in the order fulfillment process?

The seven steps are receiving inventory, storage, order picking, lodge packing, shipping, commitment and returns.

What does gild fulfilled mean?

An order is fulfilled when the client receives information technology.

How do I start an gild fulfillment business?

You'll need a solid concern plan mapping out all the important details, from facility and technology costs and location plans to concern prospects, sales projections and the estimated upper-case letter you'll need to get started and stay afloat. Outline your objectives and make detailed plans for receiving, storage, order processing and shipping strategies. Implement your plan and make adjustments as necessary to refine and streamline your concern to optimize your profits and constantly improve customer satisfaction.

What To Consider In Selecting Order Fulfillment Services,

Source: https://www.netsuite.com/portal/resource/articles/erp/order-fulfillment.shtml

Posted by: graysonausand.blogspot.com

0 Response to "What To Consider In Selecting Order Fulfillment Services"

Post a Comment